OEM/ODM Manufacturer Rubber Silicone Extrusions - EPDM gasket silicone gasket – Chaojie

OEM/ODM Manufacturer Rubber Silicone Extrusions - EPDM gasket silicone gasket – Chaojie Detail:

Types of Silicone

![]()

If you’re wondering whether silicone rubber is the right choice for sealing, it’s time to take a closer look at these synthetic elastomers. First, we’ll examine the advantages of sealing with silicone and compare some silicone gasket materials. We’ll then categorize silicone rubber in different ways and examine some applications.

To discuss your application for sealing with silicone, please contact us.

![]()

![]()

![]()

Advantages of Sealing with Silicone

![]()

![]()

Silicones resist moisture, chemicals, heat, cold, ozone, and ultraviolet (UV) radiation. They’re also stable, flexible, long-lasting, and aesthetically-pleasing. The advantages of silicone rubber include:

Silicones resist moisture, chemicals, heat, cold, ozone, and ultraviolet (UV) radiation. They’re also stable, flexible, long-lasting, and aesthetically-pleasing. The advantages of silicone rubber include:

1. Good thermal stability and low chemical reactivity.

2. Excellent resistance to ozone, sunlight, and oxygen.

3. Consistent properties at high and low temperature.

4. Repels water, resists moisture, and forms watertight seals.

5. Good electrical insulation and excellent gas permeability.

6. Come in a range of durometers and custom colors.

7. Available in special grades and with filler materials.

Applications for Sealing with Silicone Rubber Gaskets

![]()

If you’re still wondering if sealing with silicone is the right choice, consider some uses for this versatile polymer. The examples you’ll read about aren’t the only uses for silicone, but they’re representative.

Mobile Equipment

![]()

Mobile equipment manufacturers need sealing and insulation materials that can withstand demanding conditions such as engine heat, extreme outdoor temperatures, wind, water, and mud. Examples of silicone products for mobile equipment include shaft seals, spark plug caps, radiator heating hoses, O-rings, and roller gaskets.

Mobile equipment manufacturers also need floor mats, door and window seals, and thermal and acoustic insulation. Silicone rubber isn’t used for all these applications, but engine bay insulation can have a silicone-coated fiberglass facing and a layer of open cell silicone foam. This thermal-acoustic insulation is fire-resistant and withstands continuous temperatures up to 500° F.

Defense, Aerospace and Aviation

![]()

Defense contractors need rubber for the hatch seals on military vehicles and for other demanding extreme environments. Sometimes, military-grade silicones are required. For example, MIL-DTL-83528 defines the requirements for elastomeric shielding gaskets that combine environmental sealing with protection against electromagnetic interference (EMI).

The aerospace industry also needs silicone gaskets with specialized properties. For example, silicones that meet the requirements of the A-A-59588A specification provide strong flex-fatigue resistance – a measure of an elastomer’s ability to withstand repeated flexing or bending. Standard silicones can withstand a range of temperatures, but not all silicones resist higher levels of fatigue.

Food Equipment

![]()

Food equipment manufacturers need rubber that can withstand high heat from commercial ovens and cold temperatures from freezers and refrigerators. Silicones handle these extreme temperatures and can resist the frequent cleaning that’s required with food and beverage equipment. From baking mats to oven seals, silicone rubber also resists greases and oils.

Depending upon the application, manufacturers of stainless steel and food equipment may need to use FDA approved silicones materials. FDA silicones are non-toxic, non-marking, and non-allergenic. They’re also tasteless, odorless, and resistant to the natural growth of bacteria. Not all food-grade silicones are FDA approved, however.

Enclosures and Building and Construction

![]()

Enclosure sealing with flurosilicons is used with tableting equipment in the pharmaceutical industry. Silicones are also used in the enclosures for electronic and electrical equipment. In buildings, silicone rubber can be used in window seals and door seals. With other types of built structures, silicones are used in expansion joints because these elastomers allow for thermal expansion without distortion.

With their strong dielectric properties, silicones are used with cables and cable terminations, corona-resistant insulation tubing, keyboards, and contact mats. Particle-filled silicones that provide EMI shielding are used in conductive seals because metal or metal-coated particles also provide electrical conductivity. UL 94 silicones that resist the spread of fire are used in rubber gaskets for electrical enclosures.

Medical and Healthcare

![]()

Silicones for medical and healthcare applications are used in tubing for medical devices and equipment, bellows for artificial respirators, and EMI gaskets. As with food and beverage equipment, FDA approved rubber may be required. Yet not all silicones for healthcare environments require FDA approvals. Examples include the silicone door seals in walk-in bathtubs for hospital patients.

Silicones are also used with the handles for patient lifts. A metal tube can support a patient’s weight, but stainless steel is cold, hard, and sometimes slippery. Slip-on silicone foam handles support easier gripping for greater patient safety and comfort.

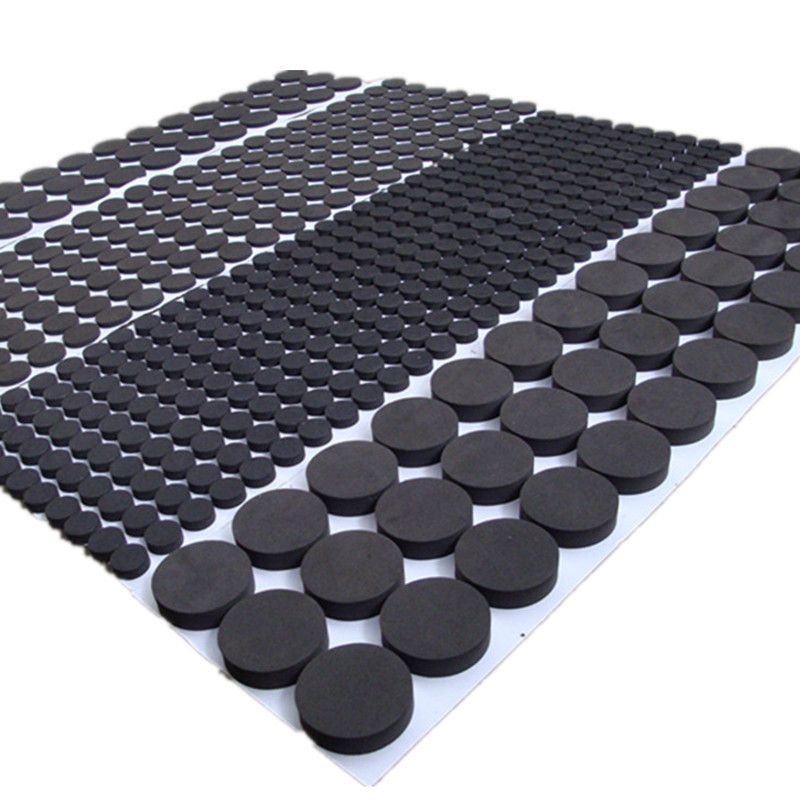

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Quality is our life. Customer need is our God for OEM/ODM Manufacturer Rubber Silicone Extrusions - EPDM gasket silicone gasket – Chaojie , The product will supply to all over the world, such as: Zimbabwe, Miami, El Salvador, Our company sticks to the principle of "high quality, reasonable price and timely delivery". We sincerely hope to establish good cooperative relationships with our new and old business partners from all parts of the world. We hope to work with you and serve you with our excellent goods and services. Welcome to join us!

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.